Omcan Manual Bun Rounder is a mechanically driven machine that can help any bakery or fast food service establishment produce uniform and round buns with ease. The machine has three levers that control the pressing, cutting and end rounding functions of the forming chamber. The size of the buns can be adjusted by using a yoke with a numerical scale.

The dough bun manual dividing rounder is a reliable and efficient solution for bakeries and food service businesses.

Thank you for viewing our quality commercial restaurant equipment online at The Foodservice Equipment Depot. We are your trusted food equipment supply store in Canada based out of Calgary, AB. The FED has answers for your how-to’s, product guides, specifications, drawings, discount pricing and shipping questions. If you are wanting to buy used or new food equipment in stock at our warehouse, please contact us today for a quote.

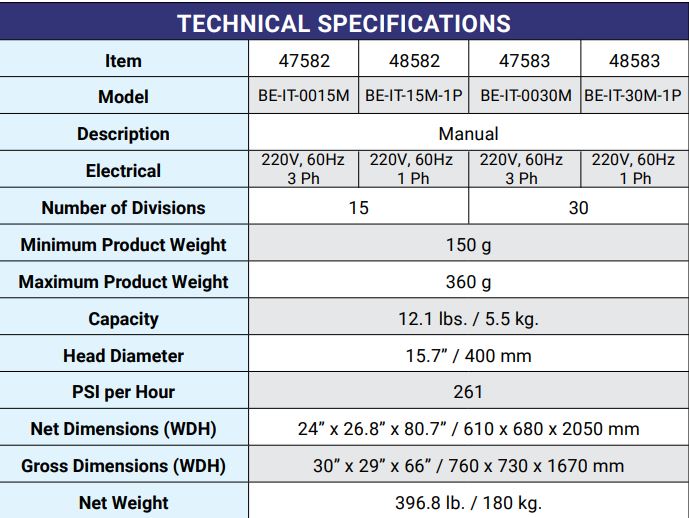

Operation Type: Manual

Electrical: 220V / 60Hz / 3

Number of Divisions: 15

Minimum Product Weight: 150g

Maximum Product Weight: 360g

Basin Capacity: 12.1 lbs. / 5.5 kgs.

Head Diameter: 15.7” / 400mm

PSI per Hour: 261

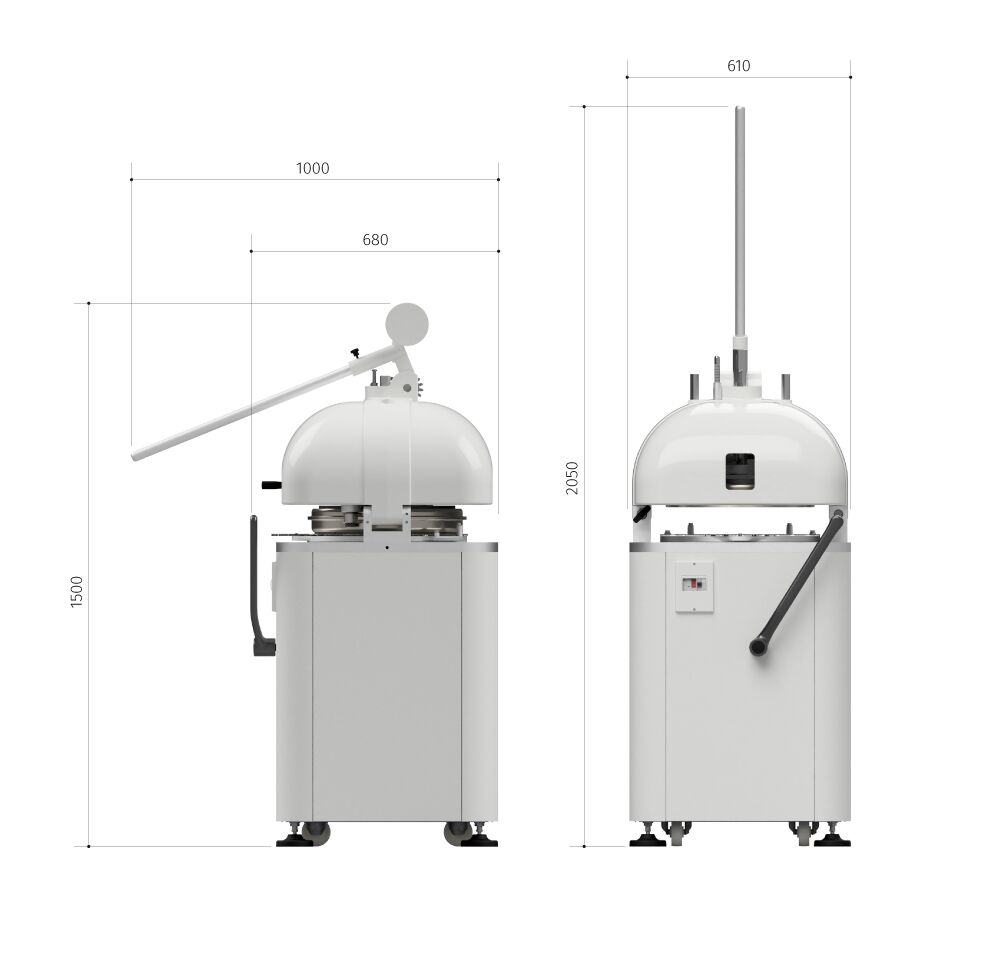

Net Dimensions: 24” x 26.8” x 80.7” / 610 x 680 x 2050mm

Gross Dimensions: 30” x 29” x 66” / 760 x 730 x 1670 mm

Net Weight: 396.8 lbs. / 180 kgs.

MATERIALS USED:

• Frame in electro-welded, painted steel

• Coating in painted steel or stainless steel

• Basins in anticorodal aluminum MG5 with anodising

• Knives and grids in stainless steel 304

• Inner cover surface and press surface made of food-grade plastic PE500

• Plates made of food-grade plastic PETG

• Ring made of aluminum with chemical nickel-plating